Confectionary

Cognituv’s automated hygiene solutions are pivotal for the food and beverage industry, focusing on ensuring stringent regulatory compliance. By effectively managing air quality and maintaining superior surface cleanliness, these systems not only optimize HVAC efficiency, but also significantly reduce chemical use. Central to maintaining industry standards, they facilitate rigorous adherence to health and safety regulations, thereby supporting operational integrity and ensuring a sustainable, compliant production environment.

Enhancing Confectionery Safety & Quality with UV-C Technology

Confectionery production requires a high level of hygiene to ensure product quality, prevent contamination, and extend shelf life. The presence of sugar, moisture, and frequent handling creates an environment where bacteria, mold, and airborne contaminants can thrive, leading to spoilage and food safety risks.

UV-C technology provides an effective, chemical-free solution for maintaining hygiene in confectionery facilities. By integrating UV-C disinfection into air handling systems, production lines, and packaging areas, manufacturers can significantly reduce microbial contamination, including mold spores, yeast, and bacteria. This helps preserve product integrity, prevent off-flavors, and maintain freshness.

Additionally, UV-C can be used to disinfect conveyor belts, storage areas, and equipment surfaces, reducing cross-contamination risks without affecting the taste or texture of sweets. With UV-C solutions, confectionery producers can achieve higher food safety standards, minimize waste, and deliver consistently high-quality treats to consumers.

Reduce Energy

Reduce Chemical Usage

Maximize Worker Safety

Maximize Food Safety

Promote Sustainability

Adhere to Strict Regulations

Mural

MURAL: Advanced Decontamination for Cold Curing/Drying Rooms

The MURAL is an innovative solution tailored for cold curing and drying environments, optimizing the preservation and quality of a wide array of products like hams, cured meats, duck breast, and fish. It seamlessly integrates into any drying room setup, enhancing product maturation and appearance.

- Targeted Decontamination: Utilizes forced air circulation to effectively remove airborne bacteria and mold, ensuring products remain uncontaminated and high-quality.

- Uncompromised Aging: The device maintains the natural aging process while preventing the proliferation of unwanted microorganisms, preserving the product’s intended flavor and texture.

- Efficient Disinfection: Quickly achieves a 99% disinfection rate against a variety of bacteria, enhancing safety and quality without significant time investment.

Enhance your cold room’s efficiency and product quality with the MURAL’s specialized decontamination capabilities.

Barricade

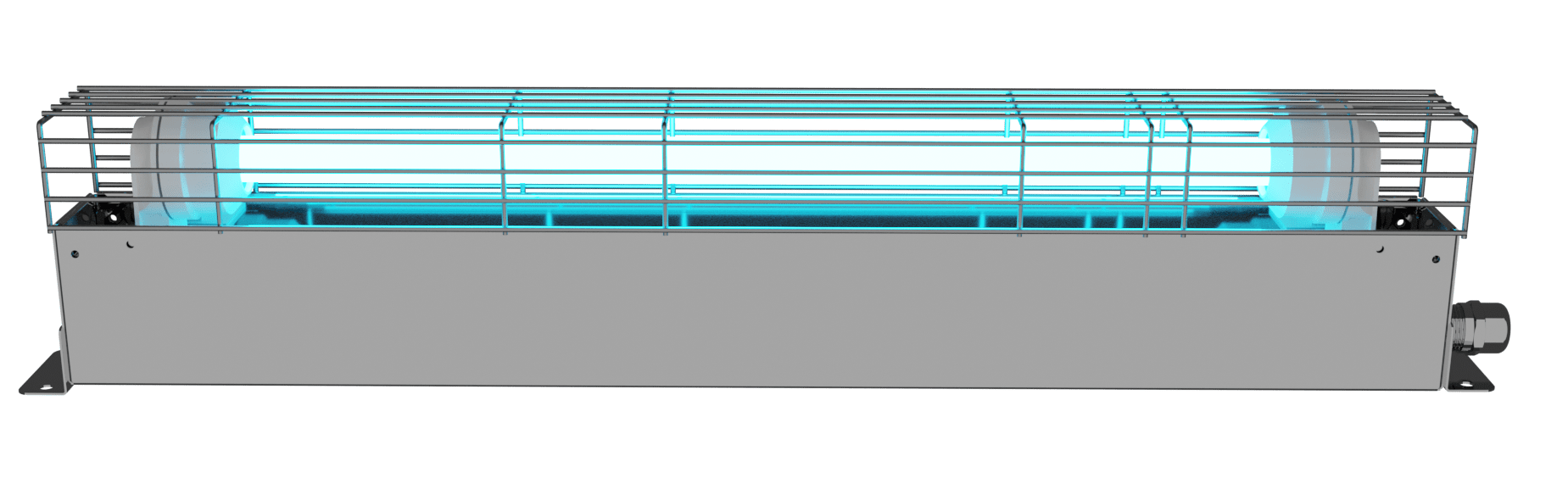

Barricade: Streamlined UV-C Disinfection for Food Industry

The Compact Barricade delivers targeted UV-C disinfection for food processing surfaces, available in stainless steel or anodized aluminum with lengths from 50 to 160 cm. It features an IP55-rated durable design, adaptable with parabolic or standard reflectors to enhance surface germicidal action.

- Durable and Efficient: Built to withstand varied conditions, ensuring lasting performance with optimized lamp efficiency.

- Focused Disinfection: Engineered to sanitize intricate areas, perfect for food facility surfaces and equipment.

- Installation Ease: Allows easy daisy-chaining of multiple units, ensuring comprehensive space coverage with minimal complexity.

The Compact Barricade offers a reliable, efficient solution for maintaining stringent hygiene standards in the food industry.