Biofilm Management

What Are Biofilms?

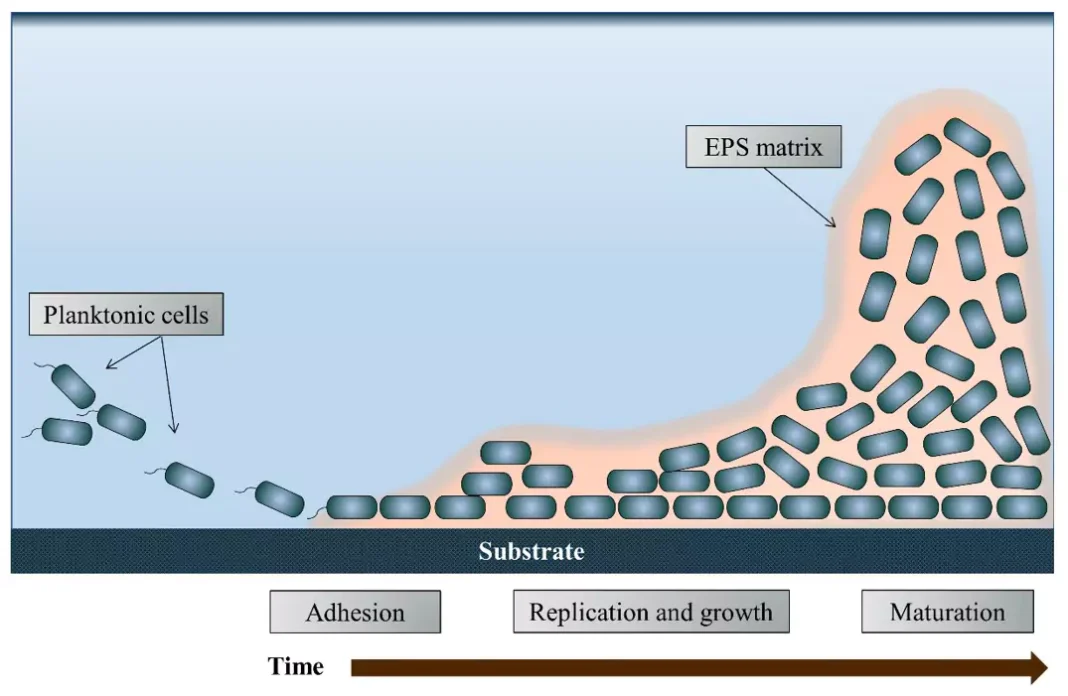

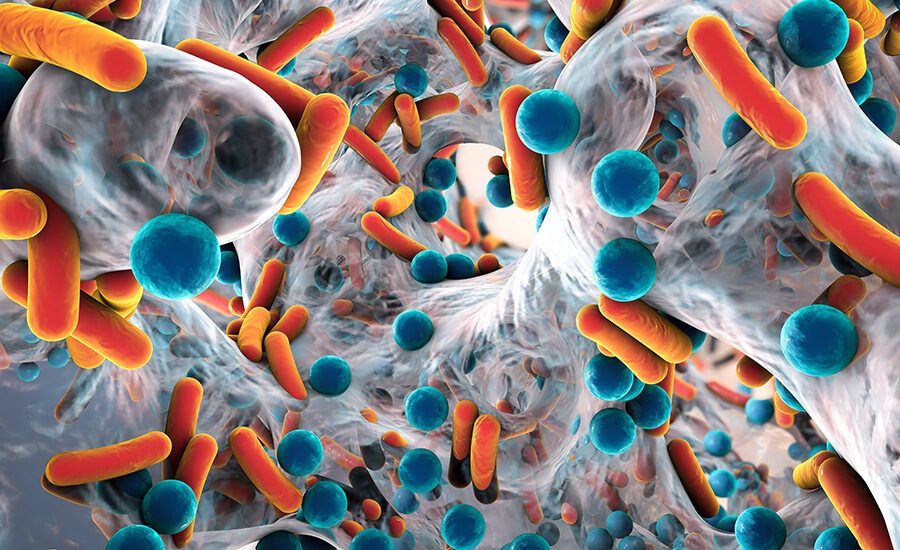

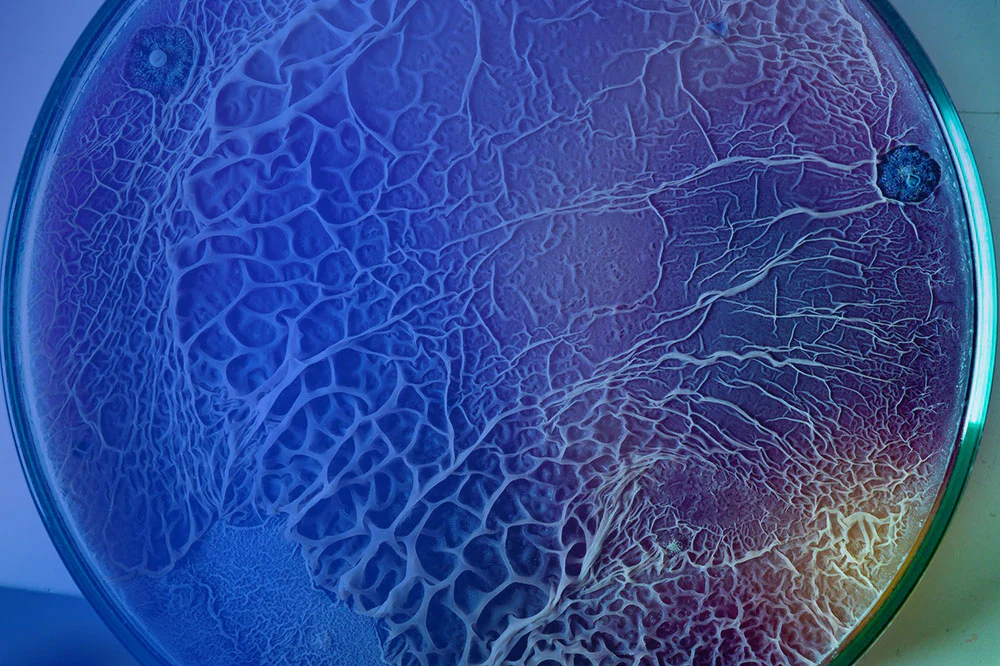

Biofilms are communities of microorganisms that stick to surfaces and create a protective layer called extracellular polymeric substance (EPS). This shield helps them grow quickly and spread within days.

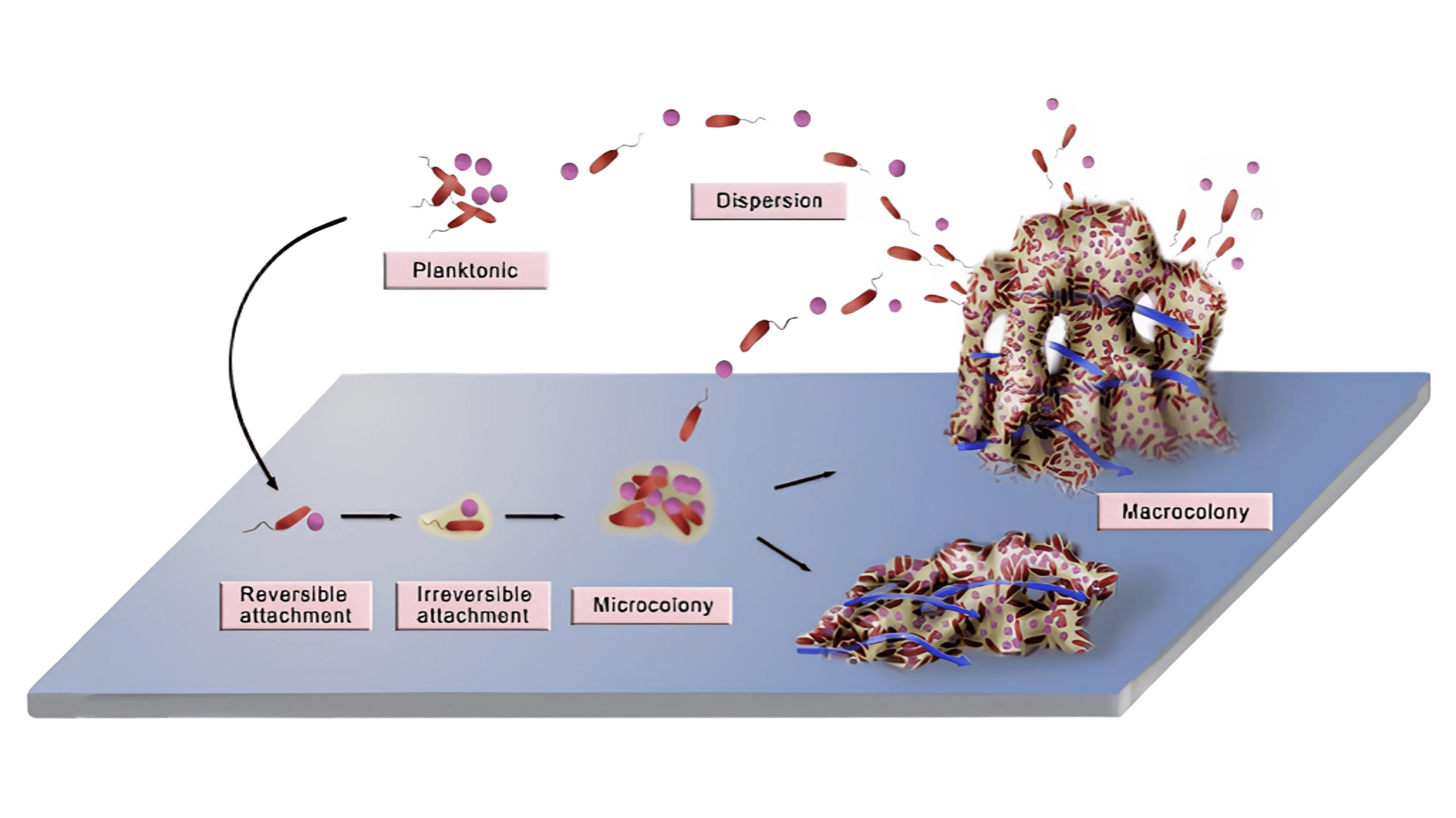

How Biofilms Form:

How Biofilms Form:

- Attachment: Free-floating bacteria stick to a surface.

- EPS Production: Bacteria produce a protective matrix.

- Maturation: The biofilm develops stable layers with diverse microbes.

- Dispersion: Microbes release and spread to new areas.

Why Biofilm Management Matters:

Even a thin biofilm can reduce system efficiency by 10% and increase energy costs up to 4x, affecting HVAC systems, energy infrastructure, and water treatment processes.

Common Biofilms and Their Impacts:

Pseudomonas

- Industries: Buildings, healthcare, HVAC systems

- Impact: Reduced HVAC efficiency, higher energy costs, increased maintenance.

Sulphate-Reducing Bacteria (SRB)

- Industries: Oil & gas, water treatment

- Impact: Corrosion of pipelines and equipment, causing failures and costly downtime.

Legionella pneumophila

- Industries: Hospitality, healthcare

- Impact: Health risks from contaminated air and water, leading to liability and reputational damage.

Mixed Microbial Communities

- Industries: HVAC, data centers, power generation

- Impact: Higher energy use, frequent breakdowns, and intensive maintenance.

The Importance of Biofilm Management:

- Reduce Costs: Prevent increased energy use, system clogs, and high maintenance expenses.

- Improve Safety: Minimize contamination risks in healthcare, food, and water systems.

- Boost Efficiency: Continuous monitoring and targeted treatments keep systems running efficiently, saving money and mitigating health risks.

DID YOU KNOW?

There is a $4 Trillion yearly global impact from biofilms and resultant Microbially induced corrosion (MIC)

Control of Biofilms with UV Light: A Critical Review of Methodologies

This comprehensive review analyzed 58 studies published between 1998 and 2024, focusing on the application of UV light to prevent or mitigate biofilm development across various industries, including water treatment, healthcare, and food safety.

Development of UV-C Side-Emitting Optical Fibers for Biofilm Control

Researchers at the Nanosystems Engineering Research Center for Nanotechnology-Enabled Water Treatment (NEWT) developed innovative nanotechnology-enabled optical fibers that emit germicidal UV-C light along their entire length.

UV-C LED Irradiation for the Inactivation of Biofilm-bound Pseudomonas aeruginosa Bacteria

This study established a robust, bench-scale protocol to investigate the inactivation responses of Pseudomonas aeruginosa biofilms using a UV-C LED collimated beam apparatus.

Inactivation of Deposited Bioaerosols on Food Contact Surfaces with UV-C Light

This research examined the complexities of disinfecting food contact surfaces contaminated with bioaerosols using UV-C light. The study observed that UV-C microbial inactivation rates varied depending on the surface material, with different rates noted for PVC, stainless steel, Teflon, and silicon.

Preliminary Investigation of the Effect of Chemical Sanitizers and UV-C Light on Listeria monocytogenes Biofilms

This study investigated the survival of Listeria monocytogenes biofilms on stainless steel surfaces after treatments with chemical sanitizers, UV-C light, and their combination. The research aimed to assess the efficacy of these treatments in reducing biofilm viability, providing insights for controlling biofilms in food processing environments.

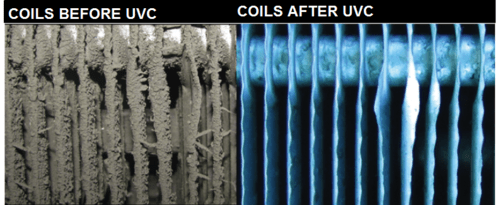

HVAC Systems and UV-C Coil Cleaning

A 60,000 square-foot facility implemented UV-C coil disinfection systems in selected rooftop HVAC units. The installation led to the elimination of biofilm on evaporator coils, resulting in annual energy savings of 86,000 kWh and improved indoor air quality.

Microfluidic Studies on Bacterial Biofilms

Researchers from the University of Toulouse and CNRS developed a microfluidic approach combined with UV-C emission to study bacterial biofilms. This method allowed precise control of biofilm formation in specific areas, facilitating extended-duration experiments and providing insights into biofilm behavior under UV-C exposure.

UV-C Light and Chemical Sanitizers Against Listeria monocytogenes

A study investigated the survival of Listeria monocytogenes biofilms on various produce-harvesting materials, including wood, nylon, and polycarbonate, after treatment with chemical sanitizers alone and in combination with UV-C light.

UV-C Disinfection in Air Handlers

The introduction of UV-C light in air handling units has been effective in preventing biofilm production. Various forms of UV-C are being studied and found to be effective in eliminating biofilm growth, contributing to improved air quality and system efficiency.

UV Photoplasma Technology in Data Centers

CCX ENERGY utilizes 254nm UV-C light, known as Germicidal UV, to kill and inactivate microbes, preventing biofilm formation on cooling coils in data centers.

Cognituv Connect is a cloud-based platform that integrates with Cognituv products, offering real-time monitoring and insights for optimal system performance.

- Continuous Data Monitoring: Real-time tracking of metrics allows for immediate response to any changes, ensuring consistent quality.

- Cloud Connectivity: Secure cloud integration enables access to data from anywhere, facilitating remote monitoring and management of your systems.

- Real-Time Measurement & Verification (M&V): Provide ongoing verification of system performance, offering transparency and assurance that processes are effective and standards are met.

- Proactive Maintenance: By analyzing data trends and performance metrics, predictive analytics improves Uptime and extends equipment life.

- Customizable Alerts: Set specific thresholds for performance indicators to receive alerts, enabling calm optimized responses.

Implementing Cognituv Connect enhances your oversight and control over your facilities.