Oil & Gas

Industry Challenge Overview

The oil and gas industry relies heavily on large volumes of water for operations such as well-fracturing, cooling, and injection. Ensuring the purity of this water is crucial to prevent environmental contamination, maintain operational efficiency, and avoid costly infrastructure damage. However, traditional chemical disinfection methods for treating wastewater and injection water present several challenges:

High Costs & Hazards: Conventional chemical treatments are expensive, pose health risks to employees, and may produce harmful by-products.

Microbial Contamination: Growth of sulfate-reducing bacteria (SRB) and other microorganisms leads to issues such as well plugging, souring (H₂S production), corrosion, and reduced oil/gas production.

Infrastructure Damage: Microbial fouling and subsequent corrosion can degrade pipelines, storage tanks, and other equipment, leading to safety hazards and escalating maintenance costs.

Economic Impact: Loss of deliverability in gas storage fields and increasing expenses related to microbial control methods cost the industry millions annually. For example, 350 storage reservoirs with over 14,000 wells can experience a 5% deliverability loss translating to approximately $100 million per year in recovery/replacement costs.

Specific Challenges

Microbial Fouling & Corrosion:

SRB and acid-producing bacteria (APB) contribute to hydrogen sulfide (H₂S) generation, which accelerates corrosion of infrastructure.

Biofilms, slimes, and microbial buildups decrease well efficiency, restrict production, and pose safety risks.

Operational & Economic Concerns:

Repeated high-pressure injection damages wells by filling permeability with inorganic precipitates, hydrocarbons, and microbial matter.

Continual need for monitoring, testing, and remediation to manage microbial-induced damage increases operational complexity and costs.

Environmental & Safety Risks:

Chemical disinfectants can lead to hazardous by-products.

Production of H₂S and other toxins endangers personnel and the environment.

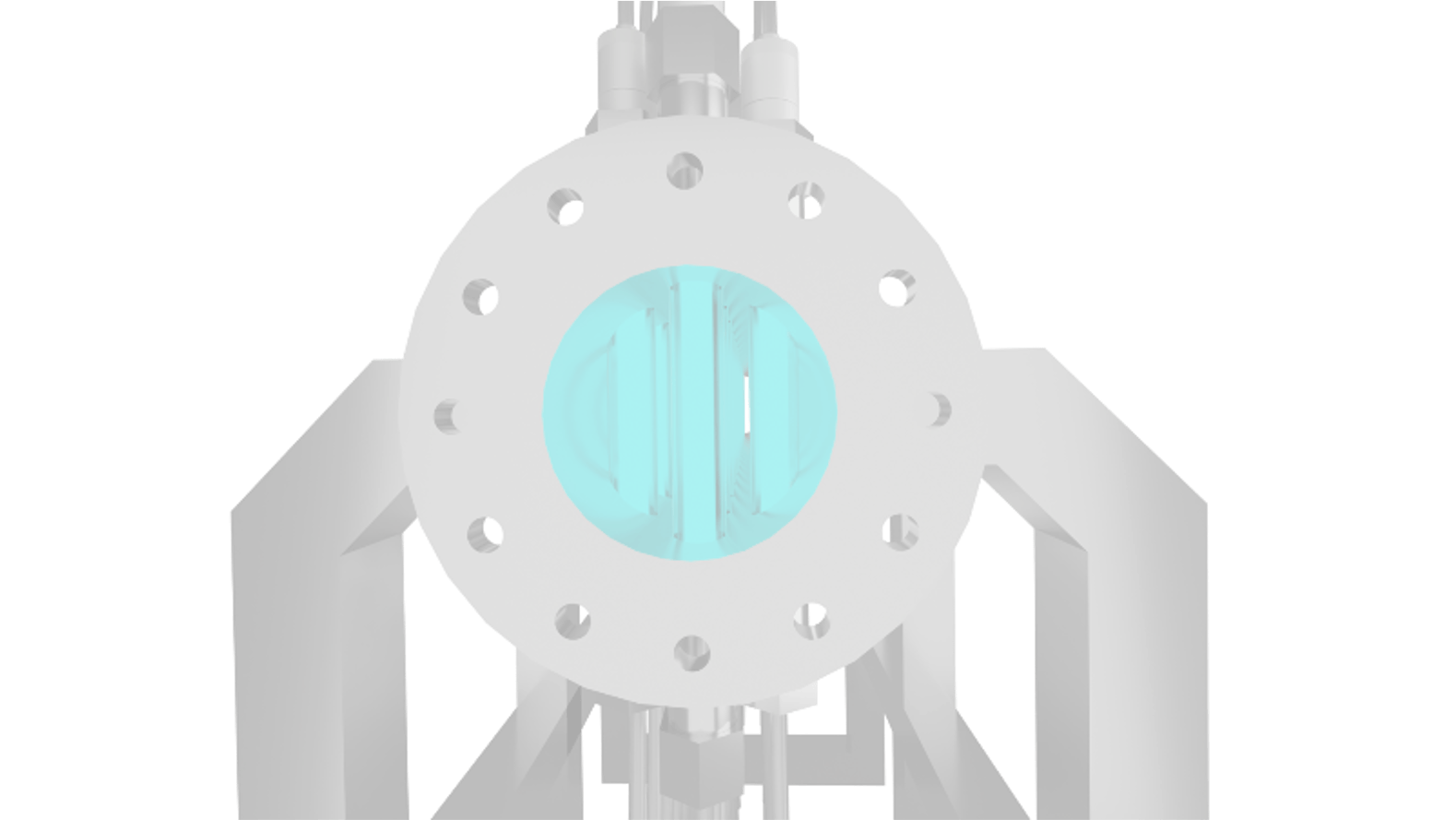

Cognituv offers a UV-C based polishing system specifically designed for the oil and gas industry—CGUV-Premium Polisher-GS.

This system uses ultraviolet (UV-C) light to disinfect water and gas streams without chemicals.

Chemical-Free Disinfection:

Utilizes UV-C light to inactivate microorganisms, including hard-to-eliminate SRB and APB.

Avoids chemical hazards and harmful by-products associated with traditional methods.

Continuous & Proven Efficacy:

Validated anti-bacterial effectiveness with ongoing and continuous UV dose verification.

Proven technology adapted from various industries to ensure reliability in harsh oil and gas environments.

Operational Efficiency & Cost Savings:

Prevents microbial fouling, thereby reducing well plugging, corrosion, and maintenance costs.

Enhances production efficiency by maintaining optimal water purity and infrastructure integrity.

Potentially saves millions by reducing downtime, prolonging equipment life, and mitigating environmental compliance costs.

Real-Time Monitoring & Integration:

Incorporates Cognituv Connect for continual analysis of particulate levels, pH, and potential bacterial presence.

Seamlessly integrates into existing operations with customizable specifications to meet unique project scopes.

Provides comprehensive testing, including real-time UV-C dose monitoring and microbiological assays.

Versatility & Sustainability:

Universal design effective on both gas and water streams.

Provides a sustainable, long-term solution by continuously suppressing microbial regrowth without ongoing chemical inputs.

Enhances safety in storage areas by eliminating biofilm buildup and unstable microbial structures.

How It Works

Evidenced-Based Treatment:

Customized UV-C treatment prescription tailored to specific operational needs and reservoir conditions.

Integration with Existing Systems:

Seamless addition to facilities such as the RNG upgrading plants, ensuring minimal disruption during implementation.

Validation & Monitoring:

Continuous monitoring to validate performance and adjust UV-C dosing as needed.

Real-time data collection via Cognituv Connect to ensure water/gas quality standards are met.

Why Biofilm Management Matters:

Even a thin biofilm can reduce system efficiency by 10% and increase energy costs up to 4x, affecting HVAC systems, energy infrastructure, and water treatment processes.

Common Biofilms and Their Impacts:

Pseudomonas

- Industries: Buildings, healthcare, HVAC systems

- Impact: Reduced HVAC efficiency, higher energy costs, increased maintenance.

Sulphate-Reducing Bacteria (SRB)

- Industries: Oil & gas, water treatment

- Impact: Corrosion of pipelines and equipment, causing failures and costly downtime.

Legionella pneumophila

- Industries: Hospitality, healthcare

- Impact: Health risks from contaminated air and water, leading to liability and reputational damage.

Mixed Microbial Communities

- Industries: HVAC, data centers, power generation

- Impact: Higher energy use, frequent breakdowns, and intensive maintenance.

The Importance of Biofilm Management:

- Reduce Costs: Prevent increased energy use, system clogs, and high maintenance expenses.

- Improve Safety: Minimize contamination risks in healthcare, food, and water systems.

- Boost Efficiency: Continuous monitoring and targeted treatments keep systems running efficiently, saving money and mitigating health risks.

DID YOU KNOW?

There is a $4 Trillion yearly global impact from biofilms and resultant Microbially induced corrosion (MIC)

Ensure Surface Cleanliness

Safety and Security

Promote Sustainability

Reduce Chemicals

Reduced Maintenance

Increase Indoor Air Quality

Cognituv Connect is a cloud-based platform that integrates with Cognituv products, offering real-time monitoring and insights for optimal system performance.

- Continuous Data Monitoring: Real-time tracking of metrics allows for immediate response to any changes, ensuring consistent quality.

- Cloud Connectivity: Secure cloud integration enables access to data from anywhere, facilitating remote monitoring and management of your systems.

- Real-Time Measurement & Verification (M&V): Provide ongoing verification of system performance, offering transparency and assurance that processes are effective and standards are met.

- Proactive Maintenance: By analyzing data trends and performance metrics, predictive analytics improves Uptime and extends equipment life.

- Customizable Alerts: Set specific thresholds for performance indicators to receive alerts, enabling calm optimized responses.

Implementing Cognituv Connect enhances your oversight and control over your facilities.